E-Commerce, Last Mile Delivery Optimization, Retail & CPG

Bringing Order to Chaos: Last-Mile Delivery Costs and How to Reduce Them

Jun 16, 2023

12 mins read

Key Takeaways

- Last-mile delivery represents 40-55% of total shipping costs, making it the most expensive segment of the logistics supply chain and a critical area for optimization.

- Failed deliveries cost businesses up to $20 per incident, while online purchase returns range from 8-88% across product categories, significantly impacting operational costs.

- Urban last-mile delivery emissions are projected to increase 30% by 2030 in 100 global cities, highlighting the urgent need for sustainable delivery solutions.

- Locus’ dispatch routing software and geocoding technology help businesses optimize delivery routes, convert ambiguous addresses into precise coordinates, and transform last-mile operations into revenue generators.

Say you purchase your coveted gadget online, eagerly tracking its journey from warehouse to your welcoming hands. Now take a moment to think about the complicated trip your gadget took to reach your doorstep.

Step into the world of last-mile delivery, the unsung hero of the e-commerce world. Customer satisfaction and keeping costs in check rests on optimal last-mile delivery operations. The question then is: how can companies maneuver this intricate, costly maze successfully?

It is no secret that customer expectations are really high these days. Naturally, the costs of meeting such expectations, especially on the delivery front are also increasing. The biggest challenge that logistics providers face is rising last-mile carrier delivery costs. Hence, businesses must proactively improve the efficiency of their last-mile delivery services.

Retailers and logistics providers should not shift the burden of costs on the consumers as it makes them unhappy and leads to churn. Thus, businesses should enhance their delivery services without hurting their profit margins.

What do you mean by last mile delivery costs in logistics?

Last-mile delivery costs refer to the expenses involved in transporting goods from a distribution center or local hub to the customer’s doorstep. This final step may seem straightforward, but it often represents the most expensive part of the delivery process, accounting for 40% to 55% of total shipping costs.

Several factors contribute to these high costs, including fuel, driver wages, route complexity, delivery time windows, failed delivery attempts, and customer-specific requirements. Each delivery involves more variables and manual effort compared to earlier stages of the supply chain, making it harder to control and scale efficiently.

Poorly managed last-mile operations can lead to rising costs, missed deliveries, and unhappy customers. Delays, confusion, and lack of visibility all affect customer experience and damage brand reputation. On the other hand, when the last mile is optimized, businesses can improve delivery accuracy, reduce costs, and build stronger customer loyalty.

Treating last-mile delivery as a strategic priority helps logistics teams unlock both operational efficiency and long-term value. Investing in the right tools and processes allows companies to transform this high-cost stage into a source of competitive advantage.

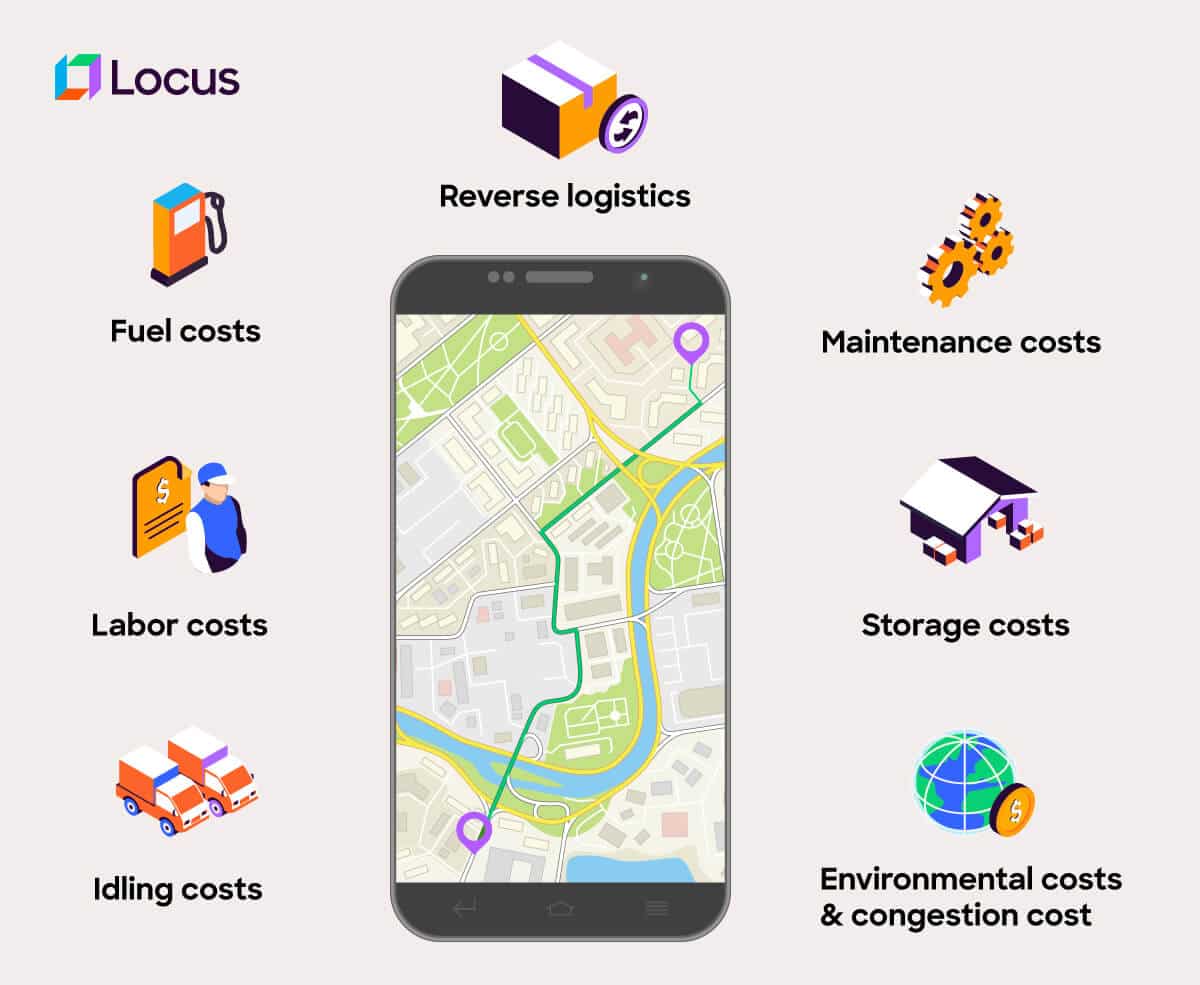

Detailed Breakdown of Last-mile Delivery Costs

As last-mile deliveries get more complex, so do the kind of costs associated with them. These include:

1. Fuel costs:

Last-mile fuel costs require careful management as they make up 25% of a truck’s operational costs over volatile price fluctuations. Urban deliveries often increase fuel consumption due to higher delivery frequency and idling, while rural deliveries add to costs due to long travel distances. Efficient fuel management can enhance route planning and capacity utilization.

Read also: How to Calculate the Cost of Transport

2. Labor costs:

The logistics industry is currently facing a significant shortage of qualified drivers in the US, causing a surge in truck driver wages, which constitute 33% of a delivery truck’s operational costs. A recent analysis by the American Trucking Associations (ATA) indicates that if existing trends persist, we could see a potential driver shortage reaching up to 175,000 by 2024.

3. Idling costs:

Idling is a considerable challenge in urban areas due to the inefficiency in fuel consumption and the potential for vehicle wear and tear. Just one hour of idling per day over a year equals 64,000 miles of engine wear, resulting in additional annual maintenance expenses of up to $9,472 per truck.

Read also: Tackling Vehicle Idling in Last-Mile Logistics

4. Reverse logistics costs:

Returns and product replacements significantly impact operational costs. The trend for quicker deliveries and specific delivery time slots increases the risk of failed or delayed deliveries, leading to high refund costs for e-commerce companies.

When a consumer decides to replace a product, logistics companies bear the costs of both reverse logistics and re-delivery, placing further strain on last-mile logistics costs. In 2021, a wide range of major product categories saw online purchase returns, with rates varying from 8% to 88%. Among these, clothing retailers had the highest percentage, with 88% of consumers opting to return their orders.

5. Environmental and congestion costs:

Delivery vehicles contribute to urban air pollution and traffic congestion. Emissions from urban last-mile deliveries are predicted to increase by 30% in 100 cities globally by 2030. Rising congestion costs due to increased delivery volumes are also a significant factor.

6. Maintenance costs:

The strain of constant start-and-stop driving increases wear and tear on vehicle components, leading to more maintenance costs. Neglected or delayed maintenance can result in costly breakdowns, extended downtime, and disruptions to the delivery schedule. Minimizing maintenance costs through proactive practices and investing in reliable vehicles is crucial for optimizing last-mile delivery operations.

7. Storage costs:

Storage costs are notable for logistics companies dealing with perishable items like pharmaceuticals and food. Many of these companies are investing in improved facilities to attract new drivers. Fleet utilization helps save last-mile costs by optimizing routing, consolidating loads, right-sizing the fleet, and enabling real-time monitoring and tracking.

Read also: A Study of Unit Economics in Last Mile Delivery

Why is last mile delivery so expensive?

Last-mile delivery is the most costly stage in the logistics chain. Despite covering the shortest distance, this final step involves a combination of factors that increase complexity, time, and resource use making it far more expensive than other stages of the supply chain. Here’s why:

1. Fewer Deliveries per Stop

Unlike bulk distribution where large quantities are delivered to a single location, last-mile delivery involves transporting small parcels to individual addresses. The cost of delivering one package to a doorstep is often the same as delivering a full load to a retail store, but without the benefit of scale. This leads to a higher cost per delivery.

2. Residential Deliveries Are More Complex

Delivering to homes presents more challenges than delivering to commercial locations. Drivers may deal with hard-to-locate addresses, lack of parking, gated communities, or narrow streets. These small obstacles add time to each delivery and reduce overall route efficiency.

3. Urban Traffic and Delays

City driving involves constant stops, heavy traffic, and frequent idling, which lowers fuel efficiency and wastes valuable time. Drivers spend more hours on the road, increasing labor costs and vehicle wear.

4. Complex Routing Needs

With dozens of stops in unpredictable locations, planning efficient routes becomes a logistical puzzle. Without advanced route optimization, drivers often travel unnecessary miles, which increases fuel and maintenance costs.

5. Low Route Density

Route density refers to the number of deliveries completed in a given timeframe. In sparsely populated or suburban areas, drivers may travel miles between stops, resulting in fewer deliveries per hour. Low route density means higher costs per delivery.

6. Failed Deliveries

Every missed delivery whether due to the customer being unavailable, unclear addresses, or restricted access adds costs. Reattempting deliveries requires more time, fuel, and coordination, and in some cases, leads to refunds or product returns.

7. Pressure for Fast Delivery

Customer expectations for same-day or next-day delivery have added pressure to logistics operations. Meeting these demands often requires larger fleets, more drivers, and shorter, less efficient routes, which all contribute to higher costs.

8. Infrastructure and Regulatory Challenges

Poor road conditions, lack of parking, and congestion increase delivery times and reduce driver productivity. On top of that, local regulations, emissions standards, and labor restrictions may require businesses to invest in new vehicles, adjust schedules, or comply with added rules all of which raise operational expenses.

Is it essential to reduce last-mile delivery costs for vehicles?

The last-mile delivery stage is significant in the logistics supply chain. These high costs, coupled with a steep increase in the volume of last-mile orders, underscore the need for reducing delivery costs to adapt to consumer demand shifts and safeguard profit margins. As this part of the process directly interacts with customers, companies must ensure efficient, on-time deliveries to uphold customer service standards. Failure to do so can lead to negative customer feedback and potential loss of clientele.

The last-mile is often the most expensive stage of logistics due to its intensive infrastructure requirements. Costs for IT, backend systems, delivery personnel, depots, and vehicle fleet’s wages accumulate rapidly, with failed deliveries adding an extra burden. Even minor glitches can lead to significant cost overruns.

Today’s retailers are grappling with increased pressure to deliver more packages swiftly and at lower costs. With customers expecting faster, more controllable, and ideally, free deliveries, reducing last-mile delivery costs has become a prerequisite for meeting these evolving customer expectations.

Curtailing last-mile delivery costs is not only desirable but essential for the sustainability and profitability of logistics companies. By reducing these costs, companies can offer better service, manage operational complexities more effectively, and keep pace with increasing customer demands.

Read also: What Makes Every Delivery More Efficient Than the Last

How to reduce last-mile delivery costs?

These innovative solutions will enable you to untangle the web of costs, without compromising on service quality. These cost-efficient, agile, and customer-focused last-mile solutions will catapult your delivery experience to success.

1. Optimize delivery routes:

A well-planned delivery route can save time and costs significantly. A dispatch routing software such as Locus can help automate your delivery route planning and turn your last mile into a revenue generator. Utilizing advanced mapping and GPS technologies, businesses can find the most efficient routes, minimizing fuel usage and wear-and-tear on delivery vehicles. Locus’ proprietary geocoding engine converts even the most ambiguous addresses into precise geographic coordinates for improved on-time delivery rates.

2. Adopt sustainable delivery modes:

A sustainable last mile can aid your business in innumerable ways. One of the many ways in which businesses can improve their green footprint is by adopting EVs, bicycles, or drones for last-mile delivery that can save on fuel expenses and maintenance costs. This eco-friendly approach can significantly cut costs while also bolstering the company’s sustainability credentials.

Why You Should Choose Carbon Neutral Shipping Today – Download E-book

3. Invest in technology and automation:

Investing in the latest technology can revolutionize inventory management, enable real-time tracking, and facilitate quicker decision-making. By minimizing human errors and inefficiencies, businesses can achieve heightened operational efficiency while simultaneously reducing costs.

4. Choose flexible delivery options:

By offering flexible delivery services like time-slot delivery, click-and-collect, or pick-up points, businesses can reduce costly failed deliveries, which according to a report by Loqate, can cost businesses up to $20 per failed delivery. These options also allow for a more balanced demand, preventing rush periods that can inflate delivery costs.

Read also: ShipFlex For Intelligent, Flexible, and Fast Deliveries

5. Partner with third-party logistics (3PL):

Collaborating with 3PL providers such as Locus can help businesses access sophisticated logistics networks and technologies without the hefty upfront investment. These partnerships can help reduce last-mile delivery costs through increased efficiency and expertise.

6. Implement predictive analytics:

Utilizing predictive analytics can provide insights into delivery patterns, customer behavior, and potential bottlenecks in the delivery process. By forecasting demand and optimizing delivery schedules and routes, businesses can enhance efficiency and reduce last-mile delivery costs.

In conclusion, the implementation of these strategies, backed by real-time data, can help businesses significantly trim their last-mile delivery costs. Balancing customer satisfaction and cost-effectiveness is crucial in the evolving landscape of ecommerce, and these tactics can aid businesses in achieving this equilibrium.

7. Offer Alternative Delivery Options

Not every customer needs doorstep delivery. Providing alternatives like in-store pickup (BOPIS), parcel lockers, or scheduled delivery time slots gives customers more control over how they receive their orders and reduces pressure on delivery fleets. These methods help improve route density and decrease failed deliveries, leading to lower operational costs.

8. Automate Customer Notifications

Keeping customers informed throughout the delivery process helps reduce missed deliveries and inbound customer support requests. Real-time updates—such as when an order is out for delivery or delayed—minimize confusion and improve first-attempt success rates, which ultimately saves time and money.

9. Leverage Crowdsourced Delivery Models

For businesses looking to expand delivery capacity without increasing fleet ownership, crowdsourced delivery using gig workers can be a flexible and cost-effective option. It reduces fixed costs and allows businesses to scale quickly during peak periods, though it’s important to monitor service quality and long-term cost trends.

10. Introduce Tiered Delivery Pricing

Introducing delivery charges based on speed or convenience allows businesses to recover part of the delivery cost while offering customers choice. While free shipping is still popular, many consumers today are open to paying for faster or more flexible delivery options, especially if slower, lower-cost options are available as well.

11. Focus on Sustainable Packaging and Reuse Programs

Encouraging the use of reusable or right-sized packaging can help reduce material waste and lower shipping costs. For example, using reusable boxes for subscription deliveries or reducing oversized packaging helps cut down on space and fuel consumption.

12. Collaborate with Local Businesses

Partnering with nearby retailers or producers to combine orders into shared deliveries can help increase delivery volume per trip. This strategy works well in rural or suburban areas where route density is naturally lower.

Conclusion

Last-mile delivery continues to be one of the most complex and costly stages of the logistics journey but it also presents the greatest opportunity for impact. Businesses that take a proactive approach to optimizing this final leg can unlock significant cost savings, improve delivery performance, and exceed customer expectations.

From intelligent route planning and sustainable delivery modes to predictive analytics and flexible delivery options, there are multiple strategies available to bring down last-mile costs without sacrificing service quality. The key lies in combining the right technology with data-driven decision-making.

Solutions like Locus empower businesses to navigate these challenges with confidence. With advanced dispatch management, real-time route optimization, and automation tools built for scale, Locus helps transform the last mile from a cost center into a competitive advantage.

Investing in smarter last-mile strategies today lays the foundation for long-term efficiency, profitability, and customer loyalty tomorrow.

Related Tags:

In Focus Webinars

In Focus: 2023 SCM Strategies for Industry Leaders

Key Takeaways Supply chain leaders face dual pressure to reduce costs due to inflation while expanding operations to meet growing consumer demands. Labor productivity in supply chains has hit decade-low levels despite technological advances, highlighting the critical need for effective technology implementation and adoption. The 3PL market is projected to reach $2.3 trillion by 2030, […]

Read more

Blog

Achieve Flawless Transporter Management Without APIs | Locus Transporter Management

Streamline coordination between shippers and transporters without API integration. Enhance visibility, automate invoicing, and improve relations with Locus Transporter Management Solution.

Read moreInsights Worth Your Time

SUBSCRIBE TO OUR NEWSLETTER

Stay up to date with the latest marketing, sales, and service tips and news

Bringing Order to Chaos: Last-Mile Delivery Costs and How to Reduce Them