Sustainability

Achieving Last Mile Sustainability: A Complete Guide

Sep 11, 2025

16 mins read

Key Takeaways

- Last-mile delivery accounts for the highest share of logistics emissions and rising urban delivery costs.

- Achieving sustainability requires data-driven routing, localized fulfillment, and fleet strategies tailored to delivery zones.

- Common challenges include fragmented networks, limited EV infrastructure, and the absence of real-time emissions tracking.

- Locus helps enterprises operationalize last-mile sustainability by embedding carbon-aware logic into dispatch, routing, and fleet decisions at scale.

Modern-day logistics is about delivering goods to customers as efficiently and sustainably as possible, sustainability being the keyword. But efficiency in the last mile often comes at a cost to the cities absorbing its impact: crowded roads, increased stop density, and longer dwell times. By 2030, delivery vehicles could add up to five minutes to the average urban commute and account for 13% of total carbon emissions in cities.

Scaled across thousands of daily shipments, last-mile inefficiencies compound quickly, draining fuel, increasing emissions, and putting pressure on delivery operations.

For enterprise logistics teams in retail and FMCG, the last mile, often the most complex and expensive segment, now plays a decisive role in overall performance as sustainability targets and regulatory demands intensify.

Driving sustainable last-mile delivery requires tighter route planning, higher delivery density, and more first-attempt success, measures that reduce emissions without compromising service. These levers help businesses stay compliant, protect margins, and earn customer trust in eco-conscious markets.

This guide explores the drivers of last-mile sustainability and how Locus helps enterprises improve performance while reducing emissions.

What is Last-Mile Sustainability?

Last-mile sustainability focuses on reducing the environmental impact of delivering goods from a local hub or warehouse to the customer. Although this stage of fulfillment covers the shortest distance, it often carries the highest environmental and operational cost due to fragmented routes, low drop density, and underutilized assets.

In major cities, last-mile delivery contributes nearly 30% of logistics-related CO₂ emissions, driven by fuel consumption from stop-and-go driving, idle time in traffic, and repeated delivery attempts caused by missed handovers or incorrect addresses. Inefficient load planning and excessive packaging add to the footprint. Emerging solutions, such as white-label deliveries combined with e-bikes and other zero-emission micromobility modes, can reduce the number of journeys by 30% and cut total delivery costs by up to 51%, creating a more sustainable and cost-efficient last mile.

What Does a Sustainable Last Mile Look Like?

A sustainable last-mile model focuses on measurable interventions that directly address these inefficiencies:

- Consolidating deliveries within neighborhoods to reduce vehicle miles traveled, for example, grouping all deliveries within a single residential block into one trip.

- Optimizing routes using real-time data to avoid traffic choke points and narrow lanes, such as rerouting vehicles based on live congestion in downtown corridors.

- Replacing diesel vans with electric vehicles or cargo bikes in dense zones where speed limits are low and drop-offs are frequent, like e-bike deliveries in Central London or Amsterdam.

- Reducing failed delivery attempts by validating addresses upfront and coordinating recipient availability, e.g., prompting customers to confirm a delivery window during checkout.

Each of these changes improves fuel efficiency, reduces idle time, and cuts emissions per order, all while supporting delivery reliability at scale.

Inefficient last-mile operations also inflate operational costs. Enterprises managing high-volume deliveries face higher fuel bills, longer driver shifts, and accelerated vehicle maintenance when routing, density, and success rates are poorly managed. Integrating sustainability into routing and dispatch decisions becomes essential, not optional, for logistics teams balancing service quality with ESG accountability.

To make these gains repeatable and scalable, enterprises require orchestration systems that embed sustainability goals into core workflows. These tools must influence how routes are planned, how deliveries are prioritized, and how performance is tracked across fleets and regions.

Ultimately, last-mile sustainability is about redesigning delivery execution to reduce emissions and operating costs at the same time, using automation, intelligent data inputs, and infrastructure-aware planning to meet both environmental and business targets.

Importance of Last-Mile Sustainability

Regulatory action, consumer expectations, and corporate climate commitments are pushing last-mile logistics toward sustainability as a core operational priority.

- Policy enforcement: London and Amsterdam’s Ultra Low Emission Zones (ULEZs) limit high-emission vehicles and impose significant fines for non-compliance. In India, Delhi and Mumbai are piloting clean delivery corridors with electric vehicle (EV) mandates and congestion pricing models. Delhi’s Deliver Electric initiative estimates that fully electrifying last-mile fleets by 2030 could avoid more than 14 million tonnes of CO₂ over vehicle lifetimes.

- Consumer scrutiny: According to McKinsey, 66% of global consumers consider sustainability in purchase decisions, extending their judgment to packaging, delivery timing, and shipment transparency. Inefficient scheduling, lack of visibility, or wasteful packaging can directly affect brand loyalty and repeat purchases.

- Internal emissions targets: Scope 3 emissions now form part of enterprise ESG metrics, placing logistics teams under pressure to deliver measurable reductions. Automated route optimization, dynamic fleet allocation, and real-time carbon tracking are becoming essential for meeting both performance and compliance objectives.

Sustainable last-mile strategies also generate operational benefits. Congestion pricing trials, such as in New York City, have shown measurable improvements in delivery vehicle travel times, demonstrating how policy can align with efficiency. Practices like zone-based routing, micro-fulfillment hubs near urban centers, and EV adoption not only lower emissions but also reduce per-package delivery costs.

By embedding sustainability into last-mile operations, enterprises position themselves to meet regulatory requirements, earn customer trust, and maintain competitiveness in markets where emissions constraints are tightening.

Key Challenges to Last-Mile Sustainability

Sustainability objectives often run up against entrenched operational realities in last-mile logistics. Overcoming these barriers requires reengineering how deliveries are planned, executed, and measured across diverse geographies and delivery models.

Disjointed multi-party delivery ecosystems

Enterprises frequently manage a mix of in-house fleets, local courier partners, and third-party logistics providers. Each operates with distinct routing software, fuel preferences, and performance standards, making it difficult to align emission-reduction strategies across the network. Zaman et al. (2022) highlight that logistics-related carbon emissions contribute to higher global healthcare costs, underscoring the broader societal and economic consequences of fragmented sustainability efforts.

Delivery volume spikes with narrow fulfillment windows

Festival seasons, promotional campaigns, and flash sales drive surges in order volume. To meet strict service-level agreements (SLAs), dispatchers often prioritize speed over load efficiency, sending out vehicles that are partially filled or following suboptimal routes. These low-density trips consume more fuel per package and significantly increase per-order emissions.

Infrastructure gaps for clean vehicle operations

Even organizations with EV adoption plans face constraints in scaling them. Charging infrastructure in secondary cities and congested delivery zones remains limited, while power grid readiness, government incentives, and vehicle replacement cycles influence rollout timelines.

Research Insight: A study in Elsevier’s Research in Transportation Business & Management warns that rapid EV adoption can destabilize power grids, causing overloads. Implementing smart charging systems to balance grid demand is critical for ensuring reliable EV operations, particularly in dense urban areas where charging demand peaks during delivery hours.

Absence of granular, real-time sustainability metrics

While most logistics teams can track delivery times and success rates, few capture live data on route-specific emissions, fuel burn by zone, or carbon intensity per order. Without these metrics, inefficiencies remain hidden until after operations conclude, forcing reactive adjustments. Real-time tracking enables teams to detect high-emission routes as they occur, make immediate changes, and sustain continuous performance improvements.

System design mismatches

Many routing platforms prioritize shortest time or lowest monetary cost without accounting for carbon impact. Without built-in environmental cost modeling, dispatchers resort to manual interventions or delayed fleet rotations, both of which limit scalability and consistency in sustainability initiatives.

Change resistance in field operations

Field teams often view environmental performance metrics as added administrative burden rather than operational enhancements. Resistance grows when sustainability targets are introduced without clear links to daily responsibilities or visible benefits. In decentralized delivery models, a lack of centralized oversight can further disconnect field teams from corporate sustainability goals, reducing buy-in. Engagement improves when organizations pair new indicators with training, support, and clear evidence of efficiency gains.

Legacy systems and fragmented decision-making underpin many of these challenges. Transitioning to a sustainable last-mile model requires integrated platforms that embed emissions considerations into every stage of planning and execution, enabling both operational efficiency and measurable environmental gains.

Strategies to Improve Last-Mile Sustainability

Improving last-mile sustainability requires targeted operational changes that cut emissions while preserving delivery speed and reliability. The following strategies are drawn from proven practices in networks with high drop densities, geographically dispersed operations, and tight fulfillment windows.

Optimize Dispatch Using Live Variables

Static routing plans often fail to account for the unpredictable nature of urban delivery. By incorporating real-time data, traffic congestion, vehicle load capacity, road restrictions, and promised delivery time windows, logistics teams can dynamically adjust routes to minimize distance traveled and idle time.

Impact Formula:

Total Route Emissions = ∑ (Distanceᵢ × Emission Factorᵢ × Load Factorᵢ)

Reducing route length or increasing load utilization proportionally lowers emissions.

According to Go Green or Go Home: Why Sustainability in the Last Mile is Crucial for Your Business, integrating live operational variables significantly improves route efficiency and reduces emissions by ensuring every vehicle is used to its optimal capacity.

Reallocate Volume to Micro-Fulfillment Nodes

Locating inventory closer to end customers reduces delivery distance and fuel consumption. Moving SKUs from centralized warehouses to micro-distribution hubs within urban centers allows more orders to be fulfilled locally. Locus research projects the global micro-fulfillment market will reach ~$10 billion by 2026, fueled by growing demand for same-day delivery and a shift toward localized logistics models.

More insights: 5 Crucial Statistics on the Future of Micro-Fulfillment Centers

Match EV Deployment to Route Patterns

Electric vans deliver the strongest ROI on short-haul, multi-drop urban routes with reliable charging infrastructure. Analyzing factors such as average route length, stop density, and charger availability helps identify high-impact deployment zones. In several Southeast Asian cities, pairing EVs with optimized delivery zoning reduced fleet emissions significantly in a single year.

Improve First-Attempt Success Using Delivery Intent Signals

Failed deliveries double the emissions for a single order. Address resolution enhancements, such as geospatial tagging, and proactive recipient confirmations via SMS or app notifications can reduce the need for reattempts. High-volume shippers using these methods have cut reattempt rates by 15–20%.

Adjust Fleet Scheduling Based on Predicted Volume

Accurate demand forecasting, built from historical order data, seasonal trends, and promotional calendars, enables more precise fleet scheduling. This prevents underfilled trips on low-demand days and ensures consistent vehicle utilization.

💡Smoothed Volume in Delivery Operations “Smoothed volume” refers to balancing delivery demand evenly over time, preventing large peaks and troughs in daily workloads. In practice, this involves anticipating high- and low-volume days and distributing deliveries across shifts to keep fleet capacity fully engaged, reducing excess mileage and fuel use.

Monitor Emissions as a Delivery-Level Performance Metric

Integrating Artificial Intelligence (AI) and Internet of Things (IoT) sensors into delivery operations enables real-time emissions tracking. These systems collect granular data on fuel consumption, idling patterns, and CO₂ output, allowing managers to act immediately on high-emission routes.

Example: A study by Yin et al. demonstrates how AI-powered monitoring systems use IoT inputs to predict and track CO₂ emissions with high precision. This not only improves the accuracy of sustainability reports but also provides actionable insights to reduce emissions during live operations.

Integrating these strategies into core routing, planning, and performance systems ensures that environmental goals are met without sacrificing service quality or delivery timelines.

Best Practices for Sustainable Last-Mile Delivery

Enterprise logistics teams improve last-mile sustainability by embedding targeted, data-driven methods into everyday operations. These practices address the operational realities of diverse geographies, varied fleet types, and fluctuating demand patterns.

1. Align delivery models with geographic demand profiles

Urban, suburban, and rural markets require distinct routing and vehicle strategies. In dense urban zones, short-range electric vans and cargo bikes can complete multiple drops per hour while meeting low-emission zone requirements. Suburban operations gain efficiency through dynamic route stacking to maximize load factors, while rural routes benefit from hybrid delivery models that pair long-haul transport with localized drop networks.

2. Consolidate returns into existing delivery workflows

Treating returns as separate operations leads to empty backhauls and wasted mileage. Integrating reverse logistics into forward delivery routes, by scheduling pickups in the same zones or using cross-docking facilities, improves fleet productivity and reduces fuel use. According to the NITI Aayog and RMI report on India’s Mobility Transformation, a consolidated routing strategy in a multi-regional pilot reduced empty return mileage by 27%, increasing vehicle utilization and lowering transportation costs.

3. Use delivery density maps to recalibrate routing zones

Fixed zip code boundaries rarely align with real delivery demand. By analyzing order heatmaps, vehicle dwell times, and repeat delivery frequency, route engineers can redraw delivery zones to improve compactness and efficiency. Quarterly adjustments that also factor in traffic flow, fleet capacity, and emissions data help eliminate cross-zone inefficiencies, cut unnecessary mileage, and enhance vehicle productivity.

Locus’ What is Last-Mile Management? outlines how dynamic zoning can streamline routing while reducing environmental impact.

4. Embed emissions metrics into team-level dashboards

Operational dashboards often emphasize delivery speed and cost, but incorporating CO₂e per order, fuel burn per kilometer, and stop density provides direct visibility into environmental performance. When planners and dispatchers track these metrics daily, they can identify high-emission routes and make immediate adjustments rather than waiting for periodic sustainability reports.

5. Conduct structured delivery reviews with a sustainability lens

Performance reviews that include idle time, kilometers per delivery, and driver behavior (e.g., frequent braking, extended stops) expose inefficiencies that traditional SLA-focused reviews overlook. These sessions work best when delivery managers, fleet leaders, and planning teams collaborate on unified data, ensuring operational improvements align with both service and sustainability goals.

Embedding these practices into core planning and execution systems enables enterprises to reduce emissions, control costs, and maintain service quality, achieving measurable gains in both operational efficiency and environmental performance.

How a Delivery Management Platform Supports Sustainability

Sustainability goals cannot be achieved through manual planning or siloed software tools. An enterprise-grade delivery management platform embeds emissions control and resource efficiency directly into routing, dispatching, and fleet allocation decisions. Locus provides a unified system that integrates these capabilities into daily operations.

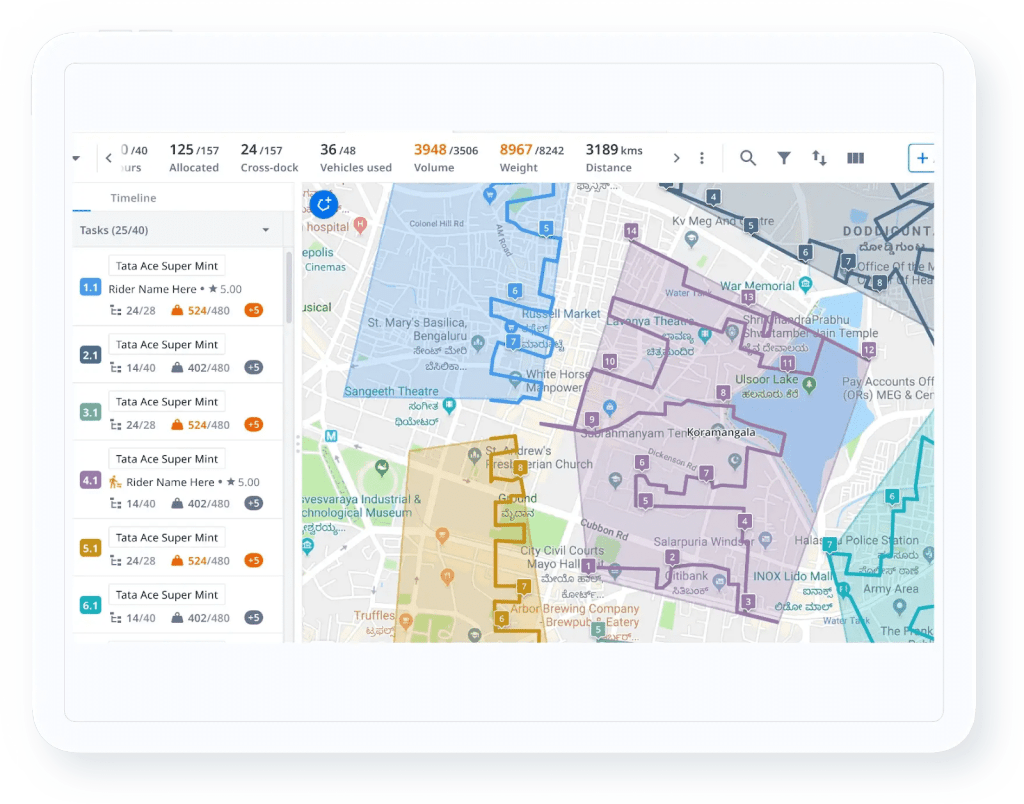

1. DispatchIQ: Route planning optimized for fuel and emissions

Locus DispatchIQ generates delivery sequences using dynamic variables such as traffic congestion, vehicle type, SLA windows, and stop density. Instead of optimizing for speed alone, the algorithm balances route duration with load efficiency and emission intensity. Configurations can be set to reduce idle duration, left turns, and route overlap, each a major contributor to unnecessary fuel use.

2. Control Tower: Emissions visibility by zone, route, and vehicle

Locus Control Tower tracks granular sustainability metrics including grams of CO₂ per kilometer, fuel use per route, and stop-level idle time. Fleet supervisors can compare performance across delivery zones, shifts, and vehicle types. Real-time updates feed into actionable route adjustments rather than static reports, enabling mid-shift corrections.

3. Geo-clustering for high-efficiency delivery zones

By analyzing historical demand patterns and delivery density, Locus uses geo-clustering to create compact, high-volume delivery zones. This zoning logic minimizes inter-zone travel, boosts stop density per route, and increases vehicle utilization. According to a 2023 study in Transportation Research Part E: Logistics and Transportation Review, which applied Freight Trip Generation (FTG) models and clustering algorithms to Lima, Peru, optimized clustering identified 11 high-efficiency zones that significantly improved logistical performance.

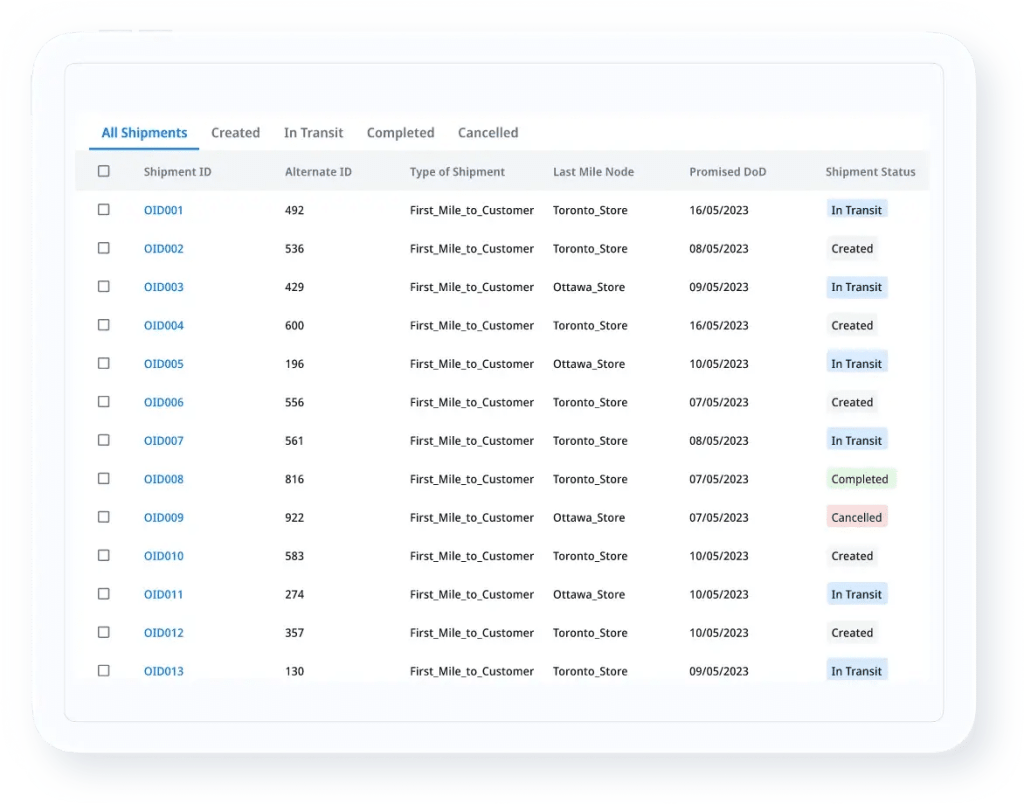

4. Real-time reassignment to prevent failed delivery trips

Failed deliveries increase both emissions and costs. Locus identifies at-risk orders, due to unavailable recipients, unclear address data, or scheduling conflicts, before routes are finalized. The platform reallocates tasks across the network based on live vehicle location and status, reducing the need for second delivery attempts.

5. EV-aware fleet routing and vehicle allocation

Electric vehicle deployment requires route planning that accounts for range, charging access, and traffic flow. Locus assigns EVs to routes that match these constraints while factoring in zone-level emission restrictions, allowing fleet managers to scale EV adoption without manual oversight.

6. Unified dashboard with emissions and SLA metrics

Locus consolidates routing efficiency, fleet performance, and sustainability KPIs into a single interface. Teams can track CO₂e per order alongside delivery costs and on-time rates, making it easier to evaluate trade-offs between environmental goals, operational costs, and service commitments.

Locus transforms sustainability from a periodic reporting task into an embedded operational capability, automated, measurable, and scalable.

Read more: Building a Green Supply Chain

Making Sustainability Operational in the Last Mile

The last mile’s high share of logistics costs and emissions makes it a strategic priority for operational and environmental performance. Leaders in the field use dynamic zone-based routing to maximize stop density, assign vehicles based on emissions profiles, and track CO₂ per order as closely as financial KPIs.

Real-time data and geo-clustering refine delivery zones to reduce inter-zone travel and improve load utilization, cutting both emissions and cost. Achieving these outcomes requires systems that combine scalability with accountability.

Locus provides that framework, integrating optimization, clustering, and live performance tracking so every dispatch is evaluated for cost, service quality, and emissions impact.

Schedule a demo to see how Locus can help you reduce emissions, optimize operations, and meet your sustainability goals.

Frequently Asked Questions (FAQs)

1. What types of vehicles are best for sustainable last-mile delivery?

Electric vans, cargo bikes, and hybrid vehicles work well for short-distance, high-frequency urban routes. Selection depends on delivery density, route length, and charging infrastructure.

2. How do failed deliveries impact sustainability?

Each failed attempt increases emissions, labor hours, and fuel usage—often doubling the environmental cost of that delivery.

3. Can small logistics teams implement sustainable last-mile practices?

Yes. Practices like delivery window confirmations, better address validation, and zone-based planning can reduce emissions without needing large fleets or tech overhauls.

4. How often should delivery zones be recalibrated for sustainability?

Reviewing and adjusting delivery zones quarterly based on demand heatmaps and stop density helps optimize routing and reduce carbon output.

5. How does a platform like Locus help scale sustainability efforts?

Locus embeds emissions metrics into routing, dispatch, and fleet assignment—making it easier for teams to meet sustainability goals without sacrificing delivery speed.

Related Tags:

E-Commerce

Last Mile in E-commerce: Definition, Importance & Benefits

Consumers all over the globe want quick, almost instant deliveries. As quick commerce becomes normal, the competition to ensure quick deliveries also intensifies. In this chaos, retailers and business owners wanting to gain market share must fine tune their last-mile fulfilment. Every eCommerce order may begin with a click, but the real test lies in […]

Read more

General

Last Mile Delivery Analytics: Key Metrics & Benefits in 2025

Learn the 10 essential last mile delivery analytics metrics that cut costs by 30%. Discover how predictive analytics and AI optimize routes and boost satisfaction.

Read moreInsights Worth Your Time

SUBSCRIBE TO OUR NEWSLETTER

Stay up to date with the latest marketing, sales, and service tips and news

Achieving Last Mile Sustainability: A Complete Guide